Do It Yourself

Do it Yourself for less than $20 per metre and save!

Just drill a 12mm hole and insert the rod!

Do it yourself with DRYROD the revolutionary new treatment for eradicating Rising (Salt) Damp. No liquids, no bottles, no mess, no smell. DRYROD damp-proofing rods are patented 12mm diameter grooved rods that carry a powerful water repellent material. They are simply inserted into 12mm holes in the mortar lines of a building. Once they are inserted, the rods will start to dry out the wall, the carrier rods will slowly diffuse water repellent deep into the damp masonry, curing to form a powerful barrier to further damp ingress. Tests have shown that DRYROD has much better diffusion characteristics than any conventional damp-proofing product.

Installing DRYROD is extremely quick and easy. The step-by-step guide on this page outlines how to use DRYROD to damp-proof a standard brick wall. The same principles apply with thicker stone walls with random mortar courses simply by drilling in the lowest possible mortar course above ground level.

Equipment

Required: Hammer Drill, 12mm Masonry Drill Bit, Tape Measure, Disposable Rubber Gloves

Other useful tools: Garden Secateurs

Preparation

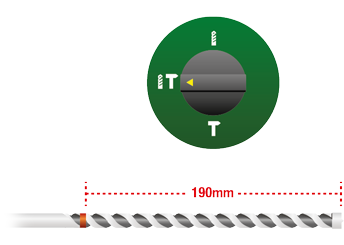

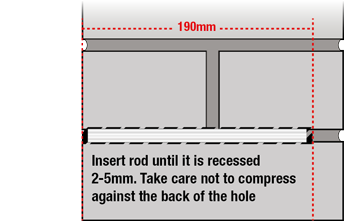

Mark your drill bit to finish 10mm from the width of the wall you wish to treat. A good quality 12mm Masonry Drill Bit is recommended for enhanced debris removal. Set your drill to rotary hammer mode and attach the suitably marked drill bit.

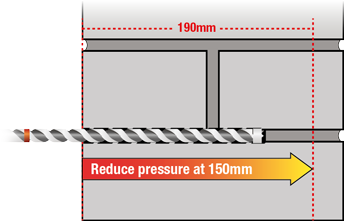

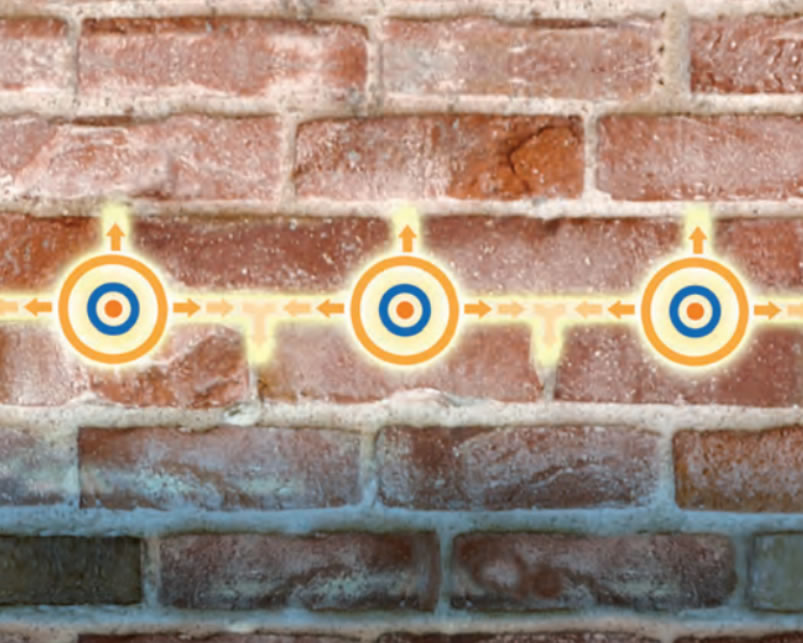

Identify the lowest horizontal mortar course that is accessible and continuous. Drill holes to the full recommended depth, at regular 120mm spacing along the wall. As the drill bit approaches the final 40mm of the intended hole depth, make sure to reduce the pressure you are putting on the drill. Excessive drilling pressure on the rotary hammer setting can result in damage to the far side of the wall.

Where the mortar is fully saturated, it may have begun to degrade, meaning that drilling dust can clump together and not clear the hole properly.

If this debris obstructs the insertion of the damp-proofing rods, re-drill the holes twice to remove any excess material.

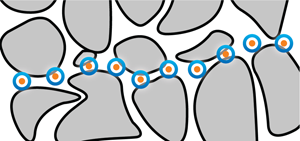

Recommended Drilling Patterns

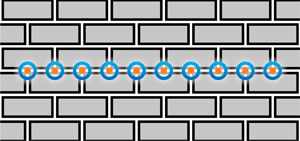

Stretcher Bond

In stretcher bond construction the mortar joints fall at approximately 12cm intervals and can be used to quickly locate your drilling points.

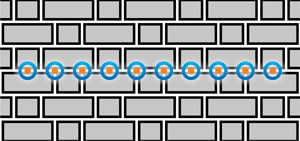

Flemish Bond

In flemish bond construction the vertical mortar joints either side of the smaller bricks and the mid point of the larger bricks lie at approximately 12cm intervals and can be used to locate your drilling points.

Irregular Stone

In irregular stone construction drilling points must be measured and care must be taken to make sure the line of the rods follow an unbroken line through the mortar at 12 cm intervals.

Damp-Proofing Rod Insertion – Wearing suitable gloves, remove the rods one by one from the packet and fully insert them into each hole. Ensure the rods are recessed approximately 5mm from the brick face, taking care not to compress the rod.

When installing internally, the performance of the rod will not be affected if the rods protrude slightly from the mortar, as a result of it being eroded at the surface. As long as the rod is inserted to the correct depth at the far side of the wall, full treatment will be accomplished and any protruding rods will be covered during redecoration.

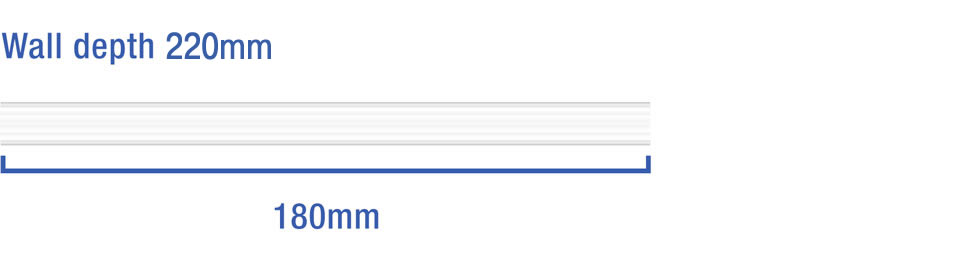

Cutting & Combining for Walls Thicker or Thinner than 220mm

A standard DRYROD® Damp-Proofing Rod is 180mm in length, and will treat a double brick wall. See tables below for other wall thicknesses.

If the wall is thinner than 220mm then cut the rods down until they are 10mm shorter than the length of the hole

If the wall is thicker than 220mm, cut a second rod down till its length is 10mm less than the excess left after inserting one whole rod.

NB: For walls over 300mm please call 0402 278 053 for advice.

What is your investment?

One Packet of 10 rods costs $70 including GST. One packet will treat 2.5 meters of single brick which equates to less than $30 per metre, a saving of over $60 per metre compared to $90 per metre on average for professional application and a saving of over $10 per metre approximately compared to other DIY systems. Huge savings with little effort on your part. They are easy, clean and accurate to apply with no wastage. The only skill required is to be able to drill holes into a mortar course.

Buy now and Save!

The world’s most rigorously tested rising damp treatment

Quick to install – unrivalled performance

The Problem

Whenever Rising Damp is diagnosed it is important to have the condition correctly treated, as failure to do so can cause damage and devaluation to any property.

It is not sufficient to simply cover up the problem with a special paint or coating in the hope that the problem will go away. Only by preventing the dampness rising up the wall in the first place can rising dampness be adequately controlled.

Chemical Treatments

Until the introduction of Dryzone the most widely employed method of achieving this was to inject water-repellent fluids into the wall under pressure.

Although this method has proven to be effective, it is known to have a number of disadvantages; for example, it introduces large amounts of liquid carrier into the wall, prolonging the drying out period. The process is also very slow and operator dependent.

The Dryzone System is fast, clean and effective

The introduction of the patented Dryzone damp-proofing cream has revolutionised the treatment of Rising Damp. The Dryzone cream is introduced by means of a simple applicator gun into a series of holes drilled into the mortar course. Once the Dryzone is installed, it diffuses to where it is most needed before curing to form a water-repellent resin.

The introduction of the patented Dryzone damp-proofing cream has revolutionised the treatment of Rising Damp. The Dryzone cream is introduced by means of a simple applicator gun into a series of holes drilled into the mortar course. Once the Dryzone is installed, it diffuses to where it is most needed before curing to form a water-repellent resin.

Dryzone has many advantages over conventional chemical injection systems

• Quick to install – no “double drilling”, no waiting for fluid to soak in under pressure

• Easy to install – less scope for operator error

• High strength formulation – does not introduce large volumes of liquid carrier into the wall

• Low hazard – non-caustic, non-flammable and not injected under pressure

• Spillage and mess virtually eliminated – no problems with fluid flooding through party walls

• Consistent application rate – easy to estimate the amount of material that will be required

• Does not require an electric DPC pump – can be used in situations where power is not available

Superior Performance

Dryzone has been tested by numerous European test houses and undergone extensive in-house testing. Results have proven that Dryzone is highly effective in a wide range of conditions and types of wall, and show that Dryzone provides:

•  Superior performance to competing products

Superior performance to competing products

• High performance even in old mortar and masonry, such as that found in Victorian buildings

• Effective treatment for cavity, rubble-infill and single leaf construction walls

Dryzone is also effective in situations where the wall is:

• Highly saturated

• Cold or warm

• Very porous

• Of high or low alkalinity

• Constructed using cement or lime mortar

The high performance formulation of Dryzone damp-proofing cream is trusted by professional installers around the world. To date over 2 million tubes of Dryzone have been sold, enough to successfully treat rising damp in over 13 million metres of 41/2” wall.

The most tested damp-proofing cream on the market

Getting It Right First Time

All methods of damp treatment cause disruption to the occupants of the affected building. It is therefore important to choose a treatment that will work first time around and avoid the need for re-treatment.

Dryzone has been formulated to provide an effective barrier to rising damp even in hard to treat situations such as walls constructed using lime mortar, rubble-filled walls, and highly saturated walls.

The effectiveness of Dryzone has been tested under more conditions than any other rising damp treatment on the market – providing assurance that it will work in walls of all types.

Precautions

Read instructions and health and safety data sheet (available upon request) before use.

Storage

Store in a cool, dry place. Protect from frost.

Applicators

Please call 0402 278 053 for details of specialist contractors who offer Dryzone installations or find it on our Contact Us page.

Further information

The Dryzone manual “Rising damp and its control” is available upon request.